Microwave plasma torch: Trade-off between CO2 conversion and Energy Efficiency

Close the Carbon cycle

Carbon dioxide (CO₂) is in the lowest energy state of carbon because it is completely oxidized. To close the carbon cycle, it is essential to capture and reuse CO2 through carbon capture and utilization. One promising method is the use of microwave plasma technology. This approach relies on electrical energy, offers rapid turn-on times, and is highly adaptable to fluctuating energy inputs. This makes it ideal for integration with intermittent renewable energy sources. Microwave plasma can split CO2 into carbon monoxide (CO) and oxygen (O2). When hydrogen (H2) is added, the resulting gas mixture forms synthesis gas, which serves as a valuable starting material for renewable carbon-based chemistry.

Energy-efficient microwave plasma process

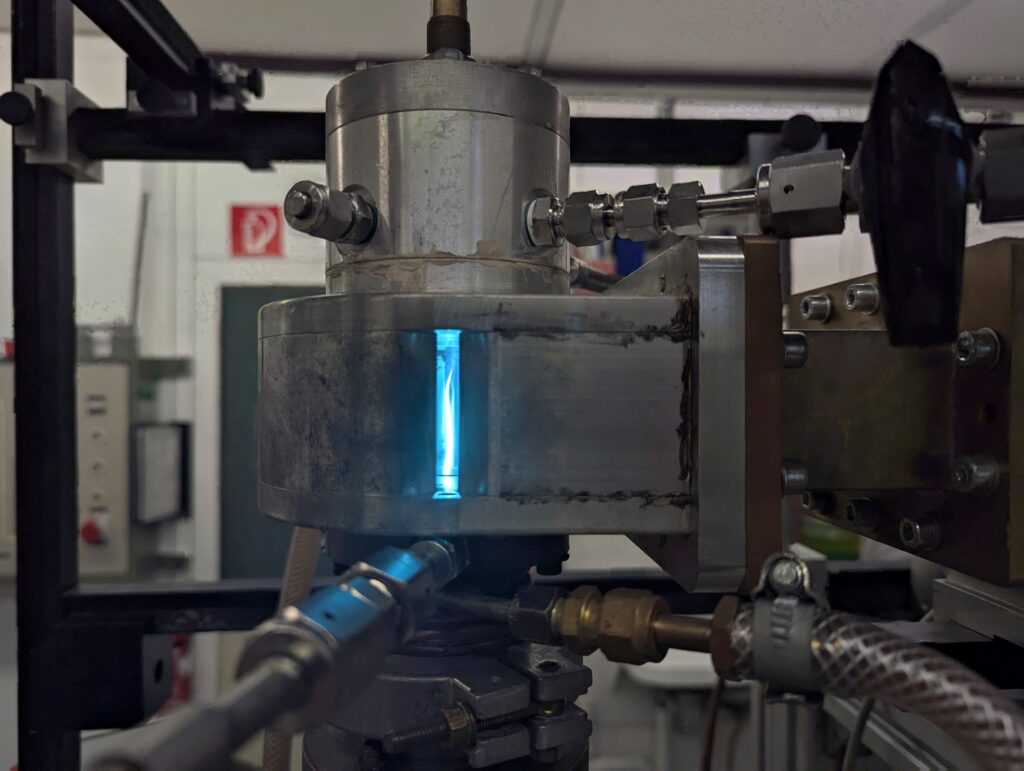

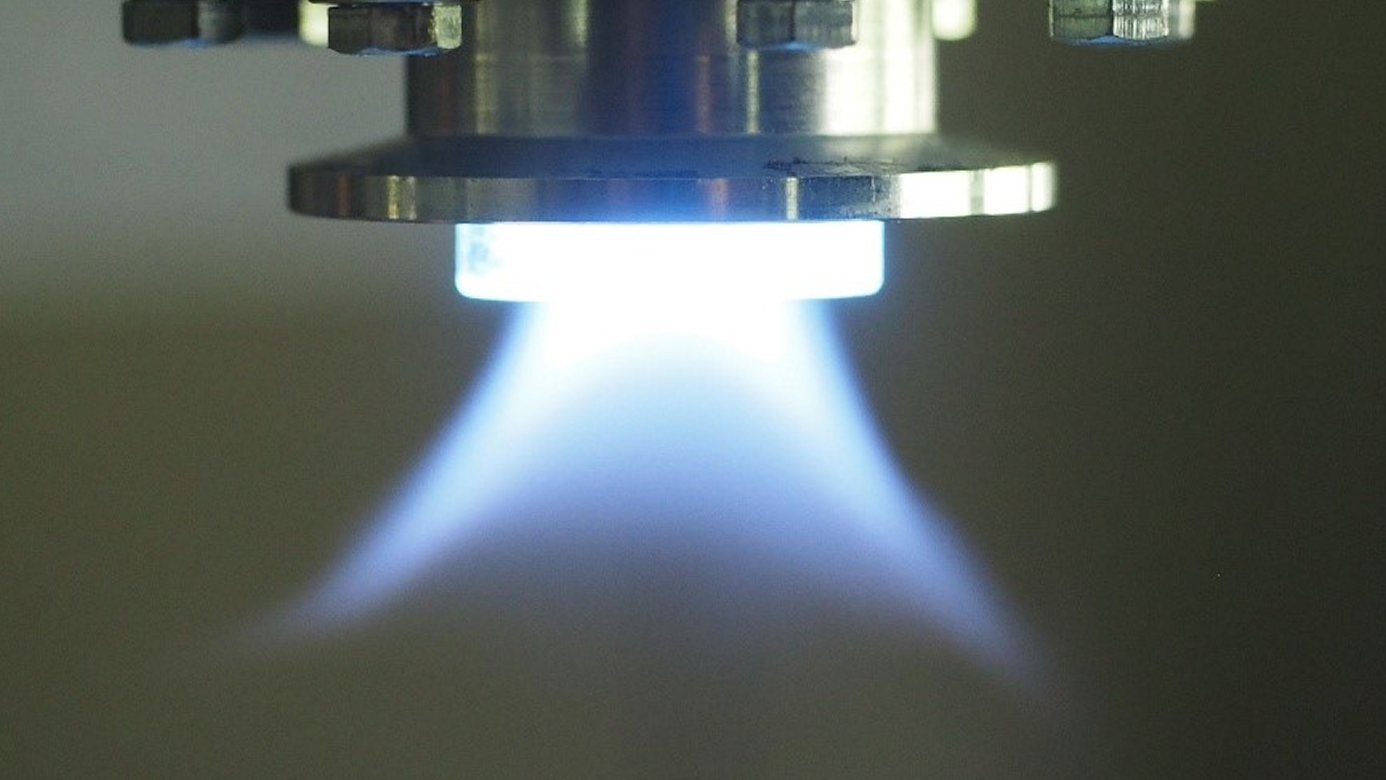

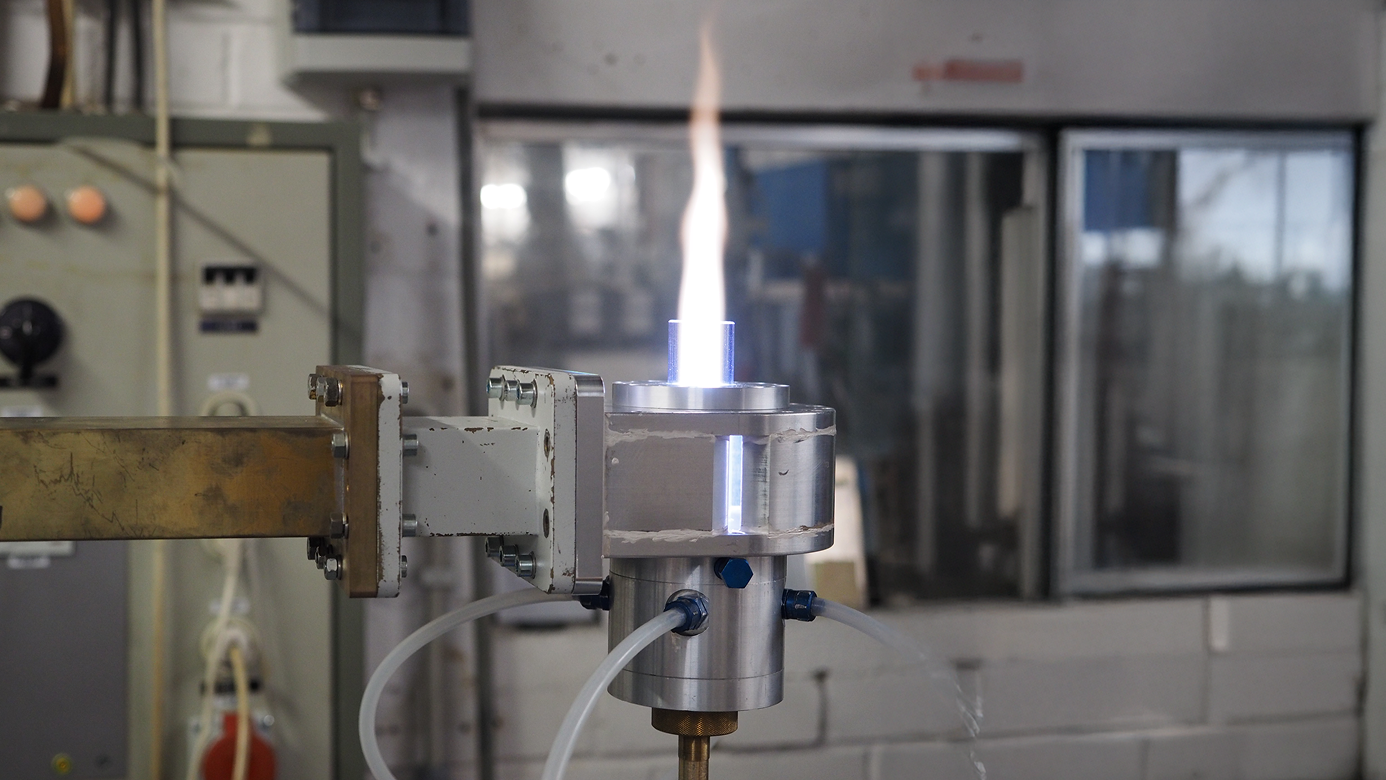

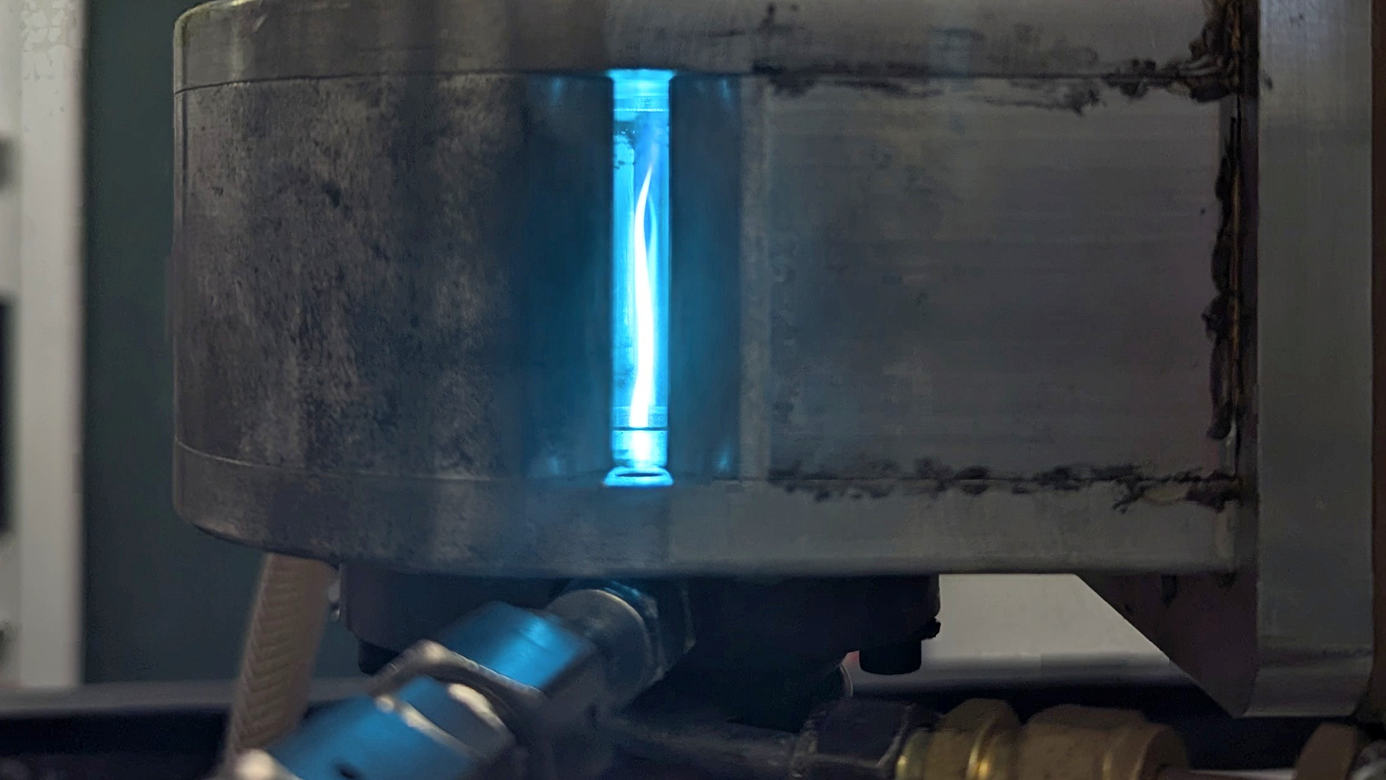

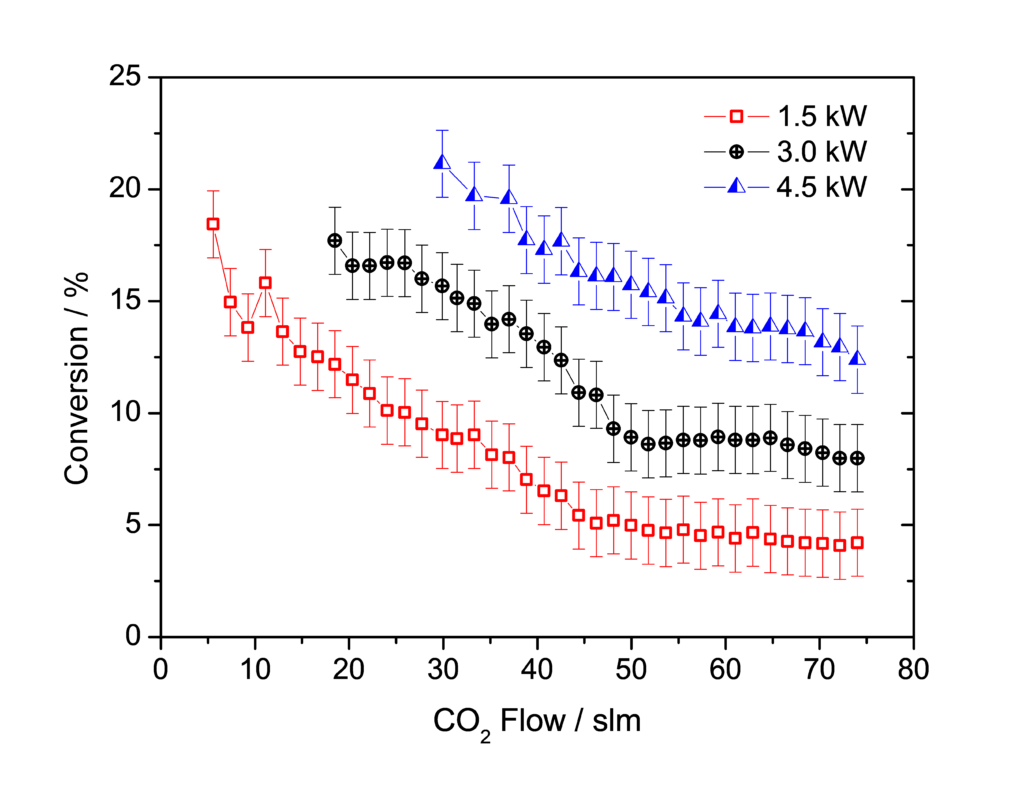

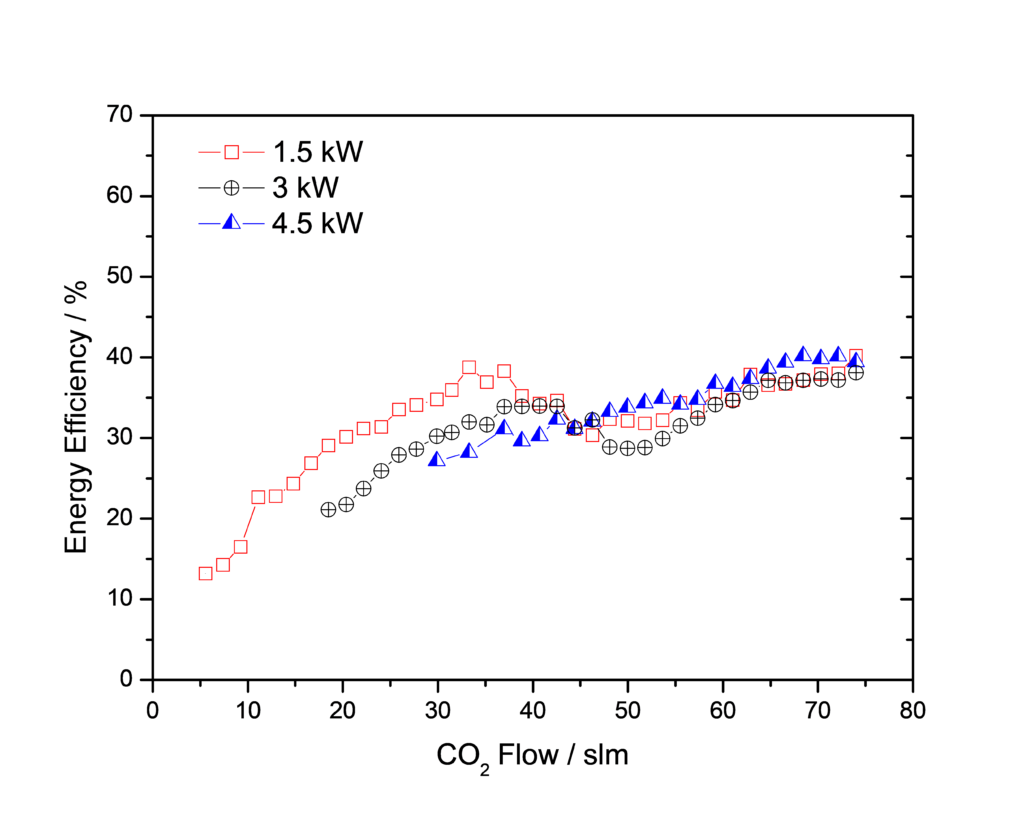

The Institute of Interfacial Process Engineering and Plasma Technology (IGVP) of the University of Stuttgart has developed an atmospheric microwave plasma torch [1] that converts CO2 into CO using renewable electricity. The IGVP performed energy efficiency studies of the CO2 plasma conversion [2]. Operating at a frequency of 2.45 GHz, the system is scaled up to a magnetron with a nominal power of 6 kW and can handle CO2 flow rates of up to 74 standard liters per minute (slm) [3]. The influence of the flow rate at three different microwave powers is shown in graphic 1. The conversion graph (left) demonstrates the conversion rate decreases as the CO2 flow rate increases, but improves with higher microwave power. In contrast, energy efficiency increases with higher flow rates. At elevated flow rates, the conversion rises linearly with microwave power, which keeps the energy efficiency constant. This operating point is particularly suitable for flexible power inputs from renewable sources and allows for maximum energy efficiency.

Influence of CO2 flow rate is shown against conversion (left) and energy efficiency (right)

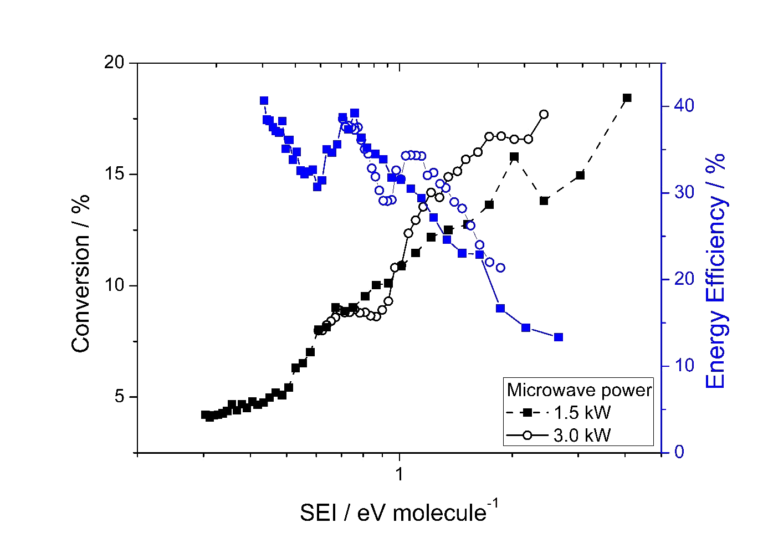

This process achieved a maximum conversion of 21 % at a specific energy input (SEI) of 1.1 eV molecule−1 with a microwave power of 4.5 kW [3]. The SEI is the ratio of microwave power to CO2 gas flow. The maximum energy efficiency of 40 % was found at gas flow rates of over 65 slm [3]. The process reveals a clear trade-off: high conversion rates are achieved at high SEI values, while high energy efficiency occurs at lower SEI values [3]. This behavior is illustrated in graphic 2 for microwave powers of 1.5 kW and 3 kW. This behavior was found to be independent of microwave power. As a result, the system can be flexibly operated in either a conversion-focused or an efficiency-focused mode, depending on the energy input.

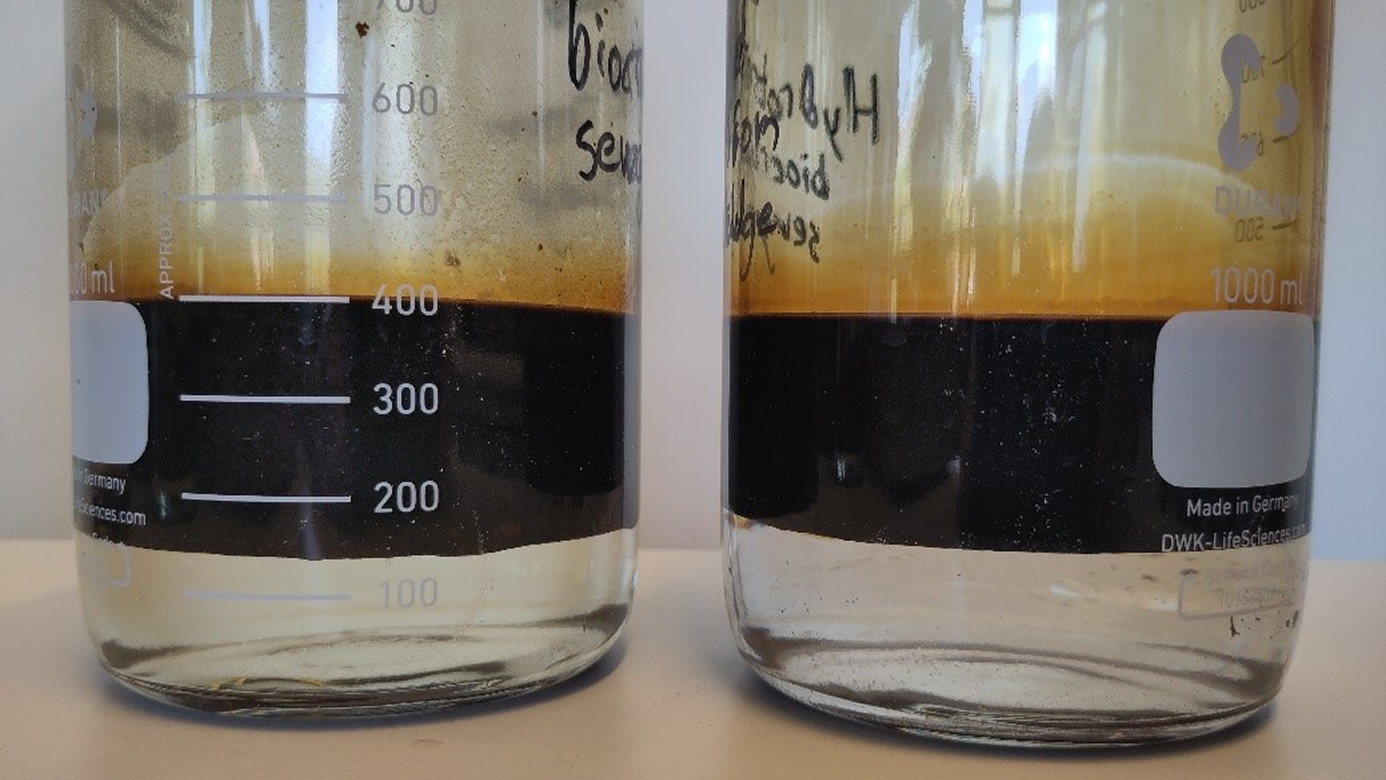

The EffiTorch project will expand the process by introducing bio-oils derived from waste materials. These oils will be injected into the hot effluent plasma behind the torch to initiate the reverse Boudouard reaction. The IGVP will investigate how the addition of bio-oils affect the composition of the products and how the microwave power and CO2 flow rate influence the process.

Key questions include:

-What impact does bio-oil have on the conversion and energy efficiency?

-Will a similar trade-off between conversion and efficiency be observed?

-Are there new mechanisms or trends that emerge?

These questions will be explored in detail as part of the EffiTorch project, paving the way for a more sustainable and flexible carbon recycling process.

Author

Marc Bresser, Katharina Wiegers

References

[1] M. Leins, et al., Plasma Process. Polym. 2009, 6 (S1), S227–S232. DOI: https://doi.org/10.1002/ppap.200930604

[2] K. Wiegers, et al., Chem. Ing. Tech. 2022, 94 (3), 299–308. DOI: https://doi.org/10.1002/cite.202100149

[3] M. Bresser, K. Wiegers, A. Schulz, M. Walker and G. E. M. Tovar, Chem. Ing. Tech., 2025, 97(5), DOI: 10.1002/cite.202400157.

CO2 Plasma, Microwave Plasma Torch, Carbon Cycle, Carbon Monoxide, Energy Efficiency