Flow Dynamics of CO₂ Plasma in the EffiTorch Project

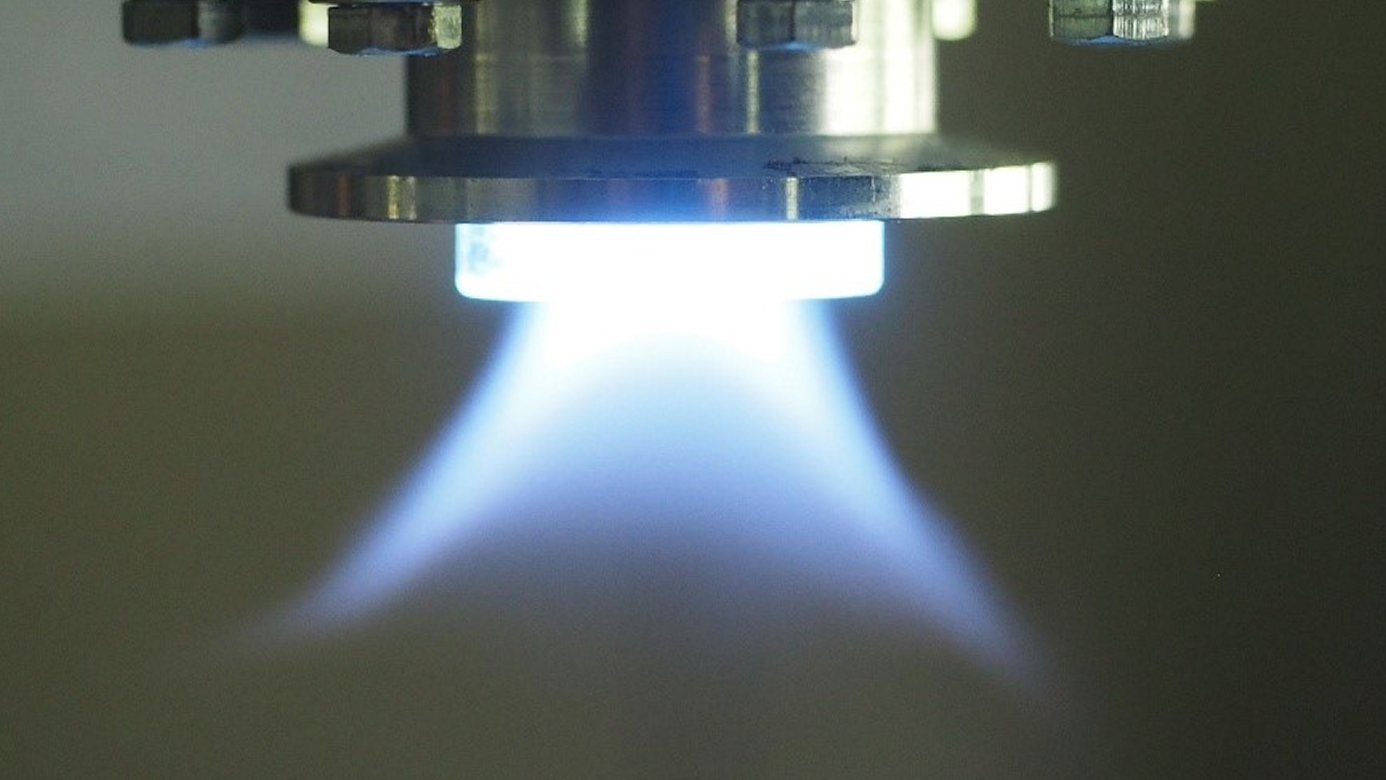

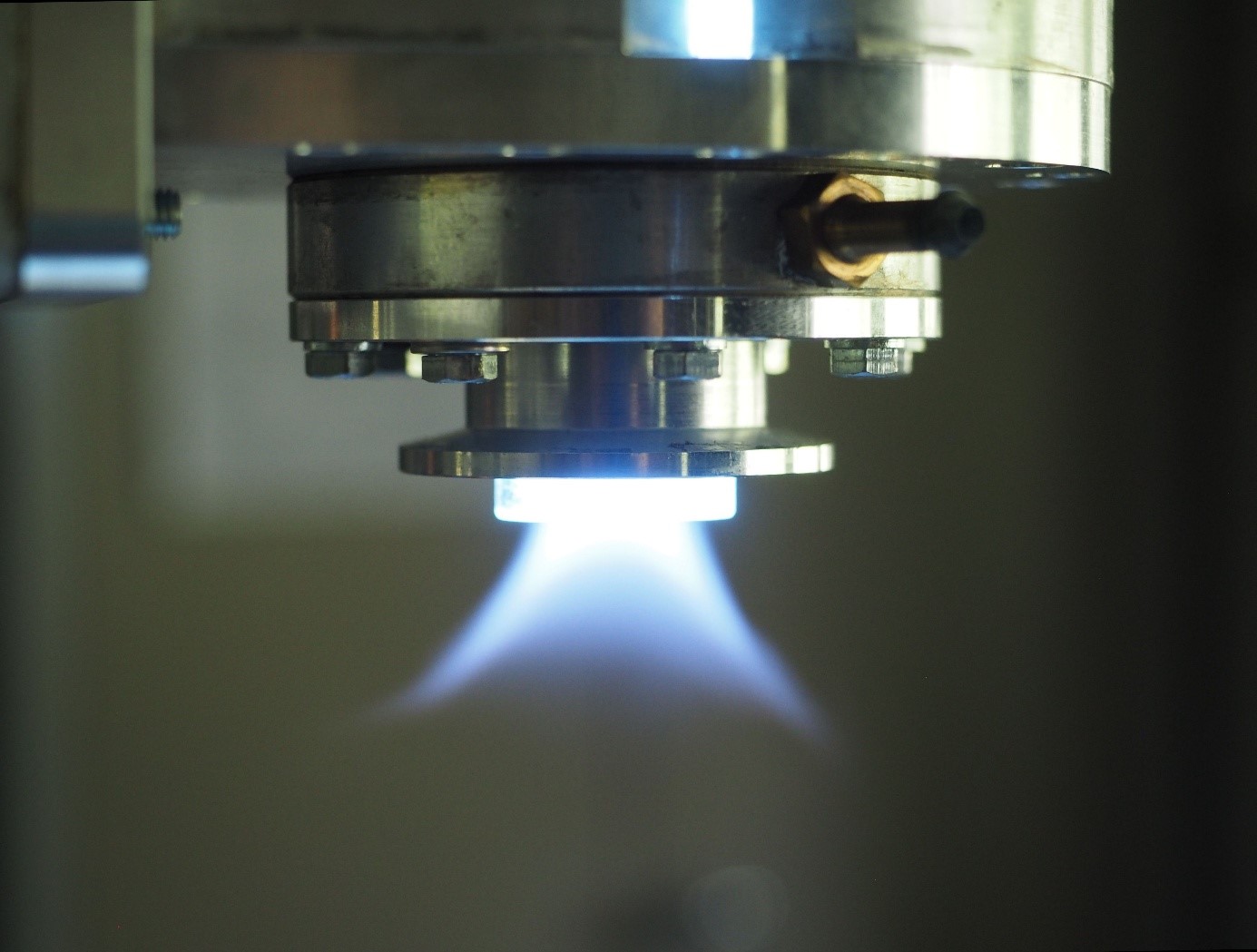

The EffiTorch project is an innovative research initiative focused on the dual objective of mitigating climate change and promoting a circular economy. Its overarching goal is to achieve the efficient utilisation of carbon dioxide (CO2) and biowaste, transforming these abundant waste streams into valuable industrial resources. At the Institute of Interfacial Process Engineering and Plasma Technology (IGVP), researchers have developed a cutting-edge system that generates a high-density, hot CO2 plasma [1]. This is accomplished at atmospheric pressure using 2.45 GHz microwaves which resonate with the gas molecules, transferring energy to them. This process creates a plasma with an electron density (ne) of approximately 1020 m⁻³, a state where the gas is highly ionised, and a gas temperature (Tg) of around 6000 K, which is hot enough to break strong chemical bonds [2,3]. The project’s primary innovative step is to introduce bio-based oils, specifically sourced from sewage sludge, directly into this extremely hot plasma.

The Rationale for Controlling Flow Dynamics

Within the energetic environment of the CO2 plasma, the strong covalent bonds of the CO2 molecules are broken. This dissociation yields highly reactive species, primarily carbon monoxide (CO) and oxygen radicals (O•). When the bio-oil is introduced, these reactive plasma species are expected to act as powerful reagents, reacting with the complex hydrocarbon molecules present in the oil. The main objective is to promote specific chemical reactions that will convert the bio-oil and the plasma species into a valuable product gas. The anticipated product is synthesis gas, a crucial feedstock for the chemical industry, which is a valuable mixture of carbon monoxide (CO) and hydrogen (H2). After the reaction, the product gas can be purified to remove any unreacted components or byproducts and then fed directly into the chemical industry for the synthesis of higher-value hydrocarbons, such as synthetic fuels or plastics.

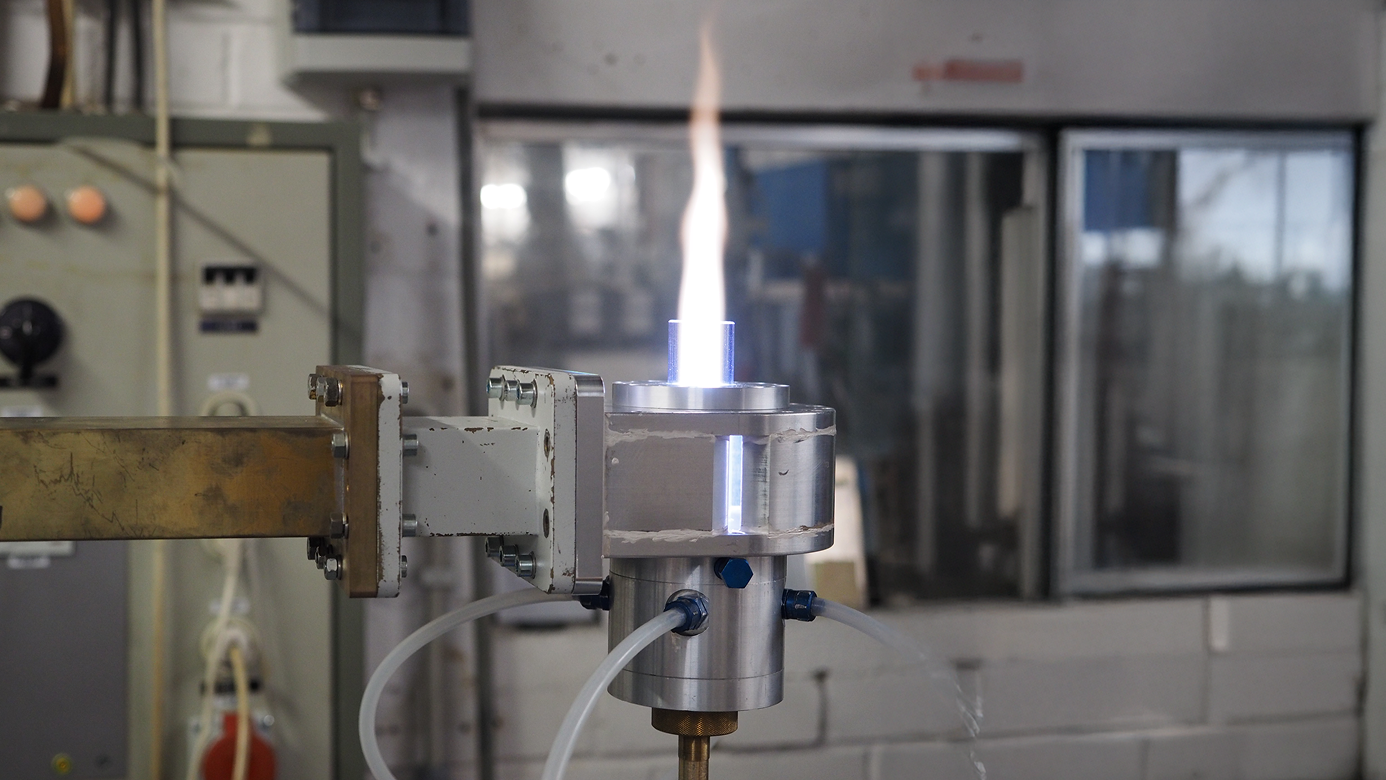

The effective control of the plasma’s flow dynamics is not just important; it is absolutely crucial for the success of this process. The process relies on achieving a high degree of interaction between the plasma and the bio-oil. The shows how the CO2 plasma is generated and then flows downwards from the microwave plasma torch. It’s designed to have a specific flow pattern: after exiting the torch, the plasma expands and forms a hollow profile due to a carefully engineered rotational flow. This hollow, expanded zone is the ideal region for injecting the bio-oil. A precise atomisation mechanism is used to break the bio-oil into a fine mist of droplets, which are then injected into this expanded plasma zone. This strategy maximises the surface area of the oil droplets, ensuring efficient mixing and rapid reaction between the highly reactive plasma species and the bio-oil components. This optimised mixing is the key to maximising the yield of synthesis gas and, ultimately, the efficiency of the entire process.

Author: Andreas Schulz and Katharina Wiegers

References

[1] A. Schulz, K. Wiegers, M. Troia, M. Bresser, S. Merli, M. Walker, G. Tovar, Novel Microwave Plasma Source for Plasma Chemistry in Gases, Chem. Ing. Tech. 2025, 97, No. 5, 487–494, https://doi.org/10.1002/cite.202400158

[2] M. Leins, M. Walker, A. Schulz, U. Schumacher, U. Stroth, Spectroscopic Investigation of a Microwave-Generated Atmospheric Pressure Plasma Torch, Contrib. Plasma Phys. 52, No. 7, 615 – 628 (2012) / DOI 10.1002/ctpp.201210058

[3] E. Carbone, F. D’Isa, A. Hecimovic, U. Fantz, Analysis of the C2 (d 3Pg – a 3Pu) Swan bands as a thermometric probe in CO2 microwave plasmas, 2019, DOI:10.48550/arXiv.1911.13121

Links

https://www.igvp.uni-stuttgart.de/en/

Keywords

CO₂ conversion, Plasma technology, Microwave plasma, Flow dynamics