Aarhus University completes first HTL biocrude hydrotreating campaign for EffiTorch

The team at Aarhus University has successfully completed their first campaign of hydrotreating biocrude derived from sewage sludge. The campaign, which also included catalyst preparation, lasted about two weeks and was carried out at AU’s pilot-scale facilities in Foulum, Denmark.

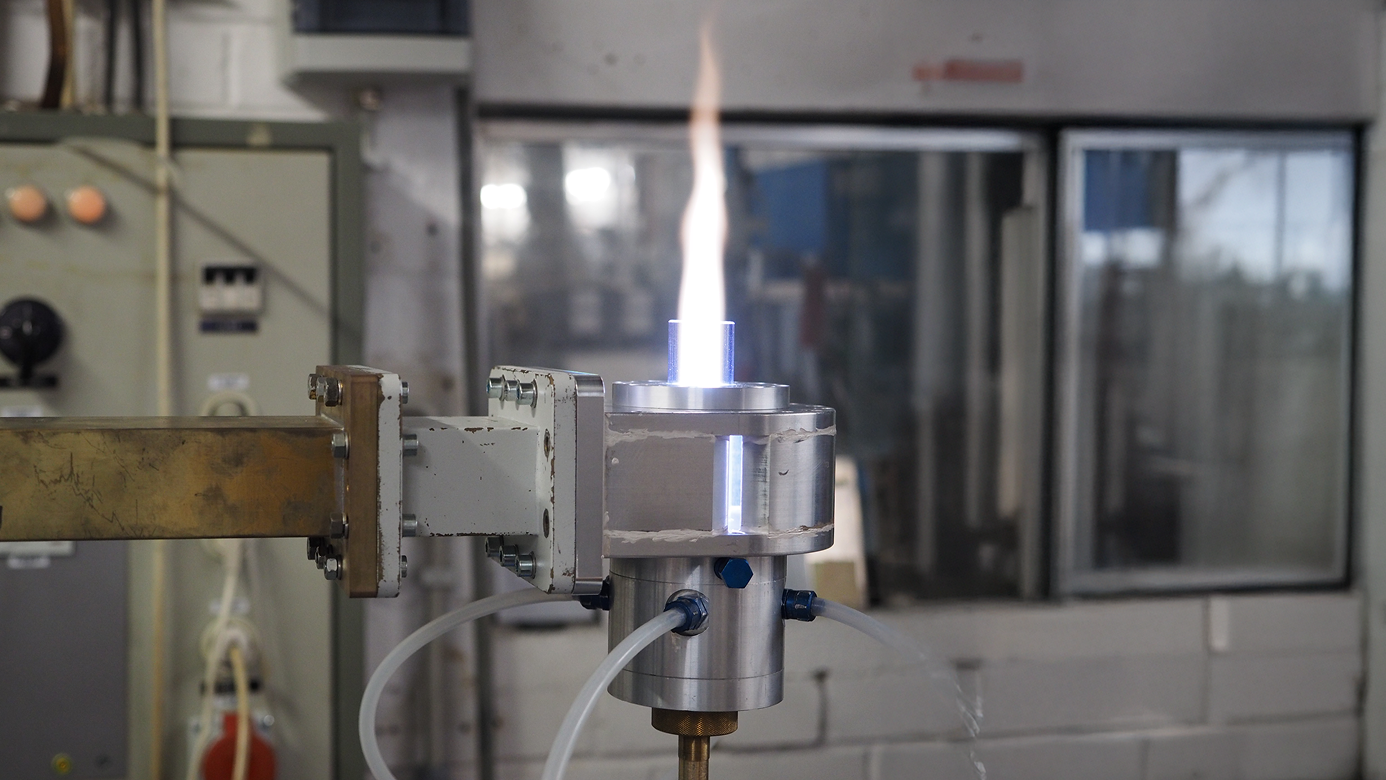

The hydrotreating setup consists of a small continuous reactor system. Two parallel piston pumps allow uninterrupted operation by alternating between feeding and refilling. Although the pumps are capable of high flow rates, the process requires a steady feed of only ~20 mg/h of biocrude. Hydrogen is supplied via a mass flow controller capable of delivering up to 60 NL/h.

The reactor itself is a dual-bed catalytic unit containing layers of CoMo and NiMo catalysts separated by glass beads. Four heating blocks maintain a controlled temperature gradient along the reactor, which has a total volume of about 70 ml. Typical operation takes place at 280–400 °C and 40–100 bar, though the system can handle conditions up to 430 °C and 180 bar.

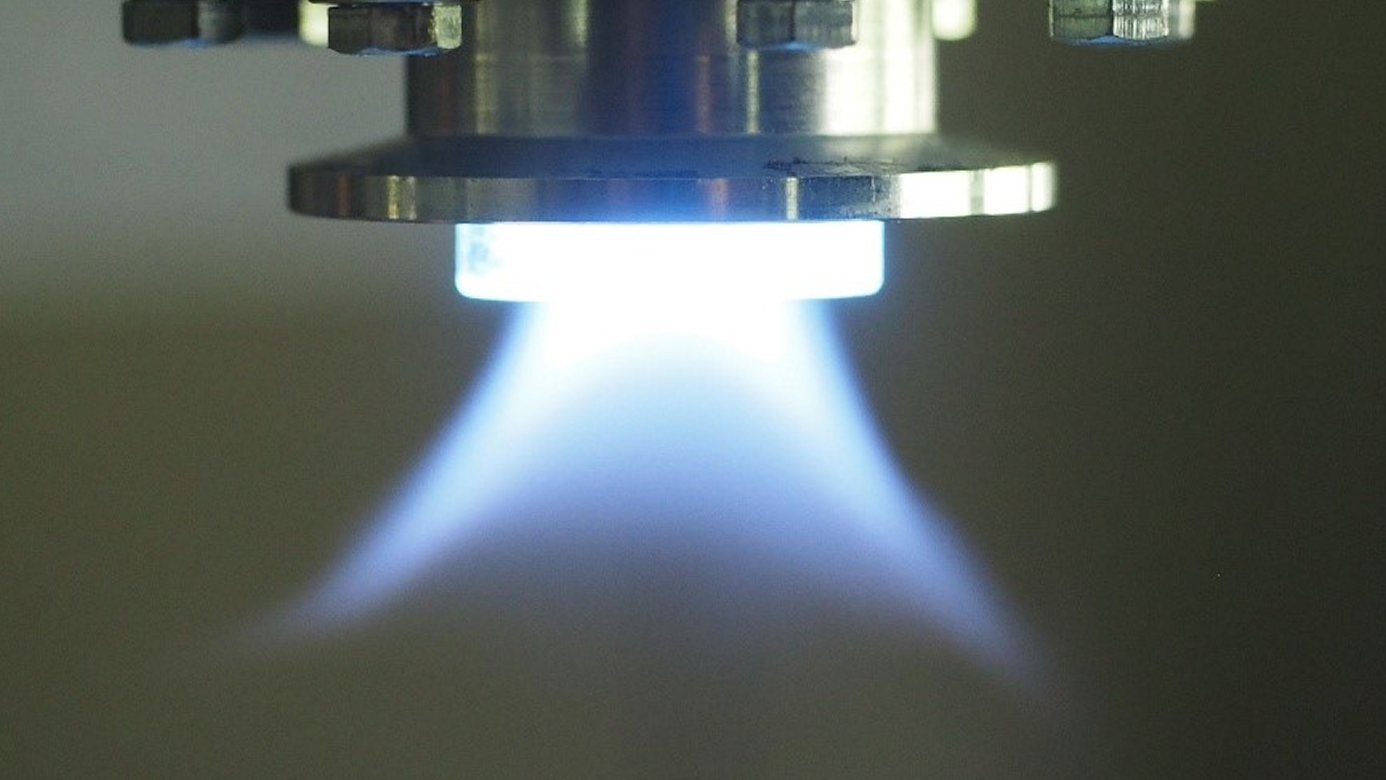

Hydrotreatment is a well-established upgrading technology for heavy fossil crudes, but its application to HTL biocrude is still relatively new. In essence, the process involves reacting biocrude with hydrogen at elevated temperature and pressure in the presence of a catalyst. The hydrogen removes impurities such as sulphur, oxygen, and nitrogen in the form of H₂S, H₂O, and NH₃, while also saturating the oil with additional hydrogen. In some cases, mild hydrocracking occurs, breaking down larger molecules into lighter compounds.

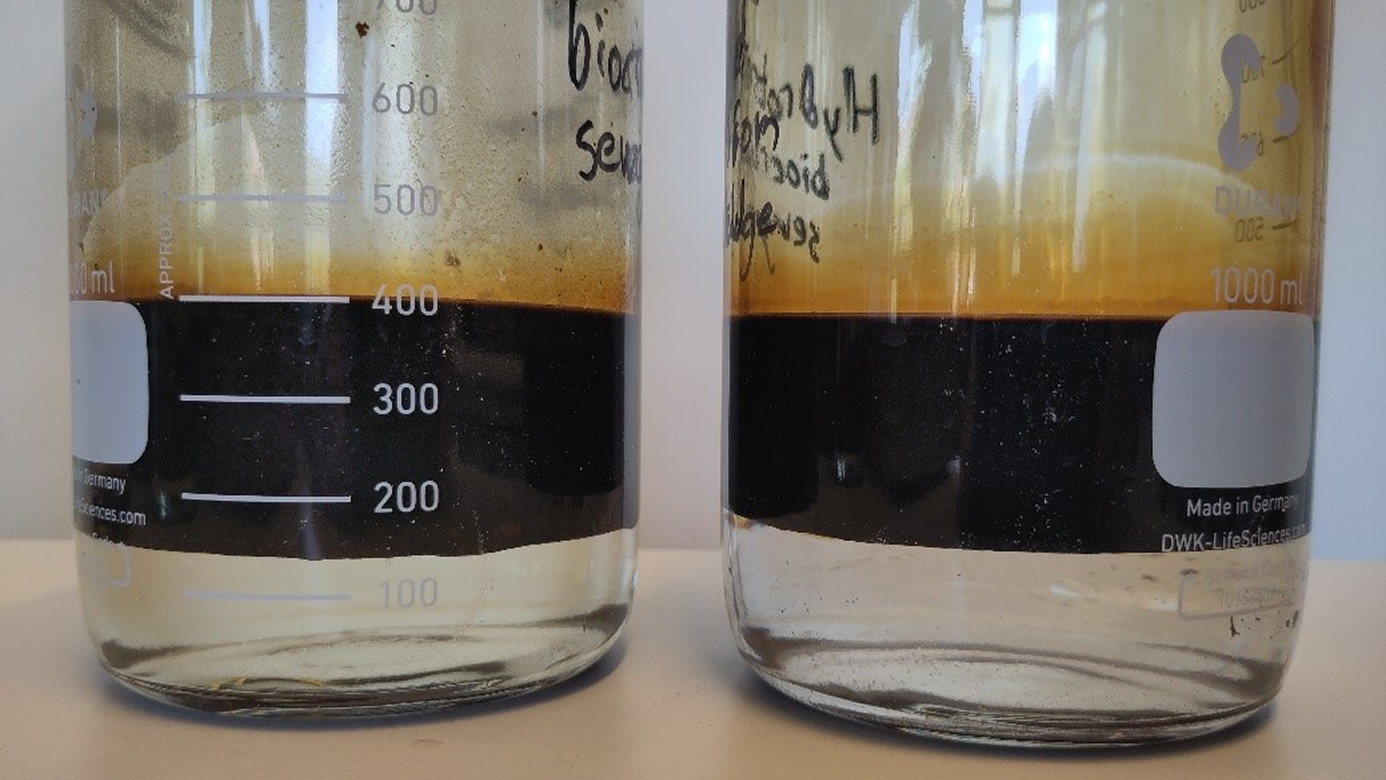

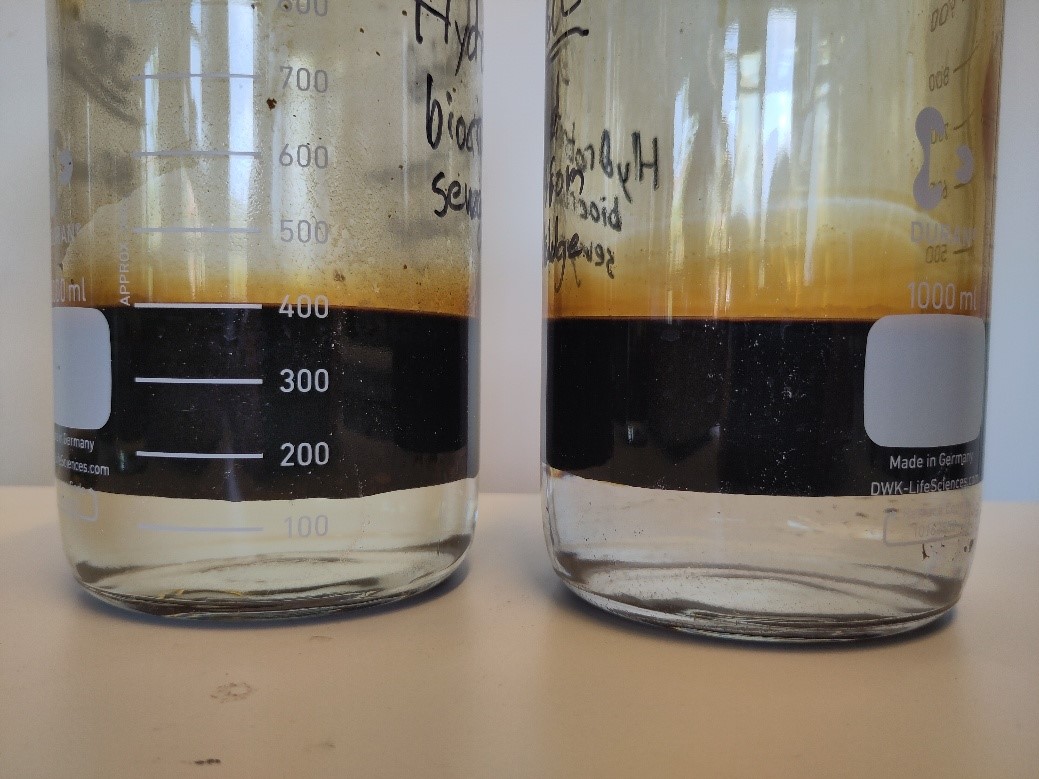

The result is a much higher-quality oil. Unwanted elements are almost completely removed, and viscosity is reduced dramatically—from a thick tar to a liquid with a flow much closer to water.

The next steps in the EffiTorch project include sending hydrotreated samples to TEKNIKER, where atomization trials will begin. At the same time, AU researchers will conduct further analyses to assess viscosity reduction under different hydrotreating conditions, from mild to severe. The hydrotreated product will also be distilled into fractions to evaluate whether specific cuts are especially suitable for atomisation.

Following these tests, additional hydrotreating campaigns will be carried out to optimise the process for EffiTorch applications. In parallel, AU will also explore alternative upgrading strategies that do not require hydrogen or catalysts, aiming to identify the most cost-effective and sustainable pretreatment methods for achieving optimal atomisation.

Author: Simon Fridolfsson

Keywords

Biofuels, Biocrude upgrading, renewable fuels, hydrotreatment of HTL biocrude, viscosity reduction, deoxygenation, denitrification, desulphurisation, hydroprocessing