Turning Sewage Sludge into a Circular Resource through Hydrothermal Liquefaction

From sewage sludge to biocrude

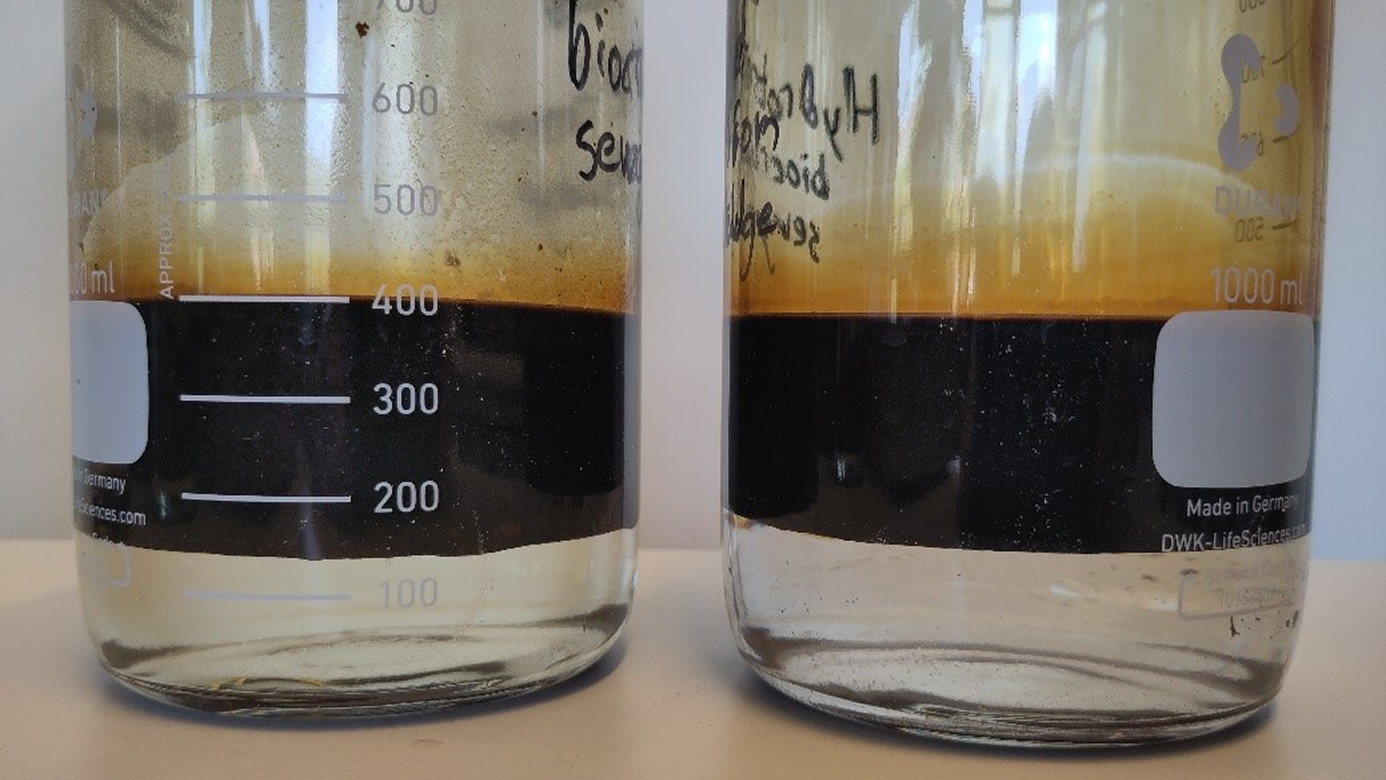

At the world’s largest academic plant for continuous hydrothermal liquefaction, what was once sewage sludge has been turned into biocrude – a renewable alternative to fossil crude oil. This process is somewhat comparable to what the Earth does in millions of years, but in under an hour.

Conversion of wet biomass

Hydrothermal liquefaction can unlike commercial thermochemical technologies, be used to convert biomass into an energy rich product without the need for drying. This can save a lot of energy when handling wet biomass, such as algae, food waste, or sewage sludge. Thus, in the scope of the EffiTorch project, Aarhus University (AU) will utilize its pilot facilities to convert sewage sludge into valuable biocrude as sewage sludge is an unwanted waste product and environmental burden.

From sewage sludge to biocrude: hydrothermal liquefaction and upgrading in EffiTorch

As Europe transitions towards a circular economy, the challenge is twofold: finding sustainable alternatives to fossil fuels and chemicals while also closing the loop on waste streams. One promising solution is to use waste itself as a resource. Over the past decade, a range of biological and thermochemical processes have shown strong potential to replace fossil-based products. However, most conventional thermochemical methods require the feedstock to be very dry, both to maintain high energy efficiency and to prevent unwanted side reactions.

Hydrothermal liquefaction (HTL) offers a different approach. In fact, it requires water. By processing a slurry of biomass and water under high pressure (150–200 bar) and elevated temperature (250–350 °C), water takes on unique properties that help break down the biomass into a mixture of valuable compounds. The main product is biocrude—a thick, tar-like liquid with similarities to fossil crude oil.

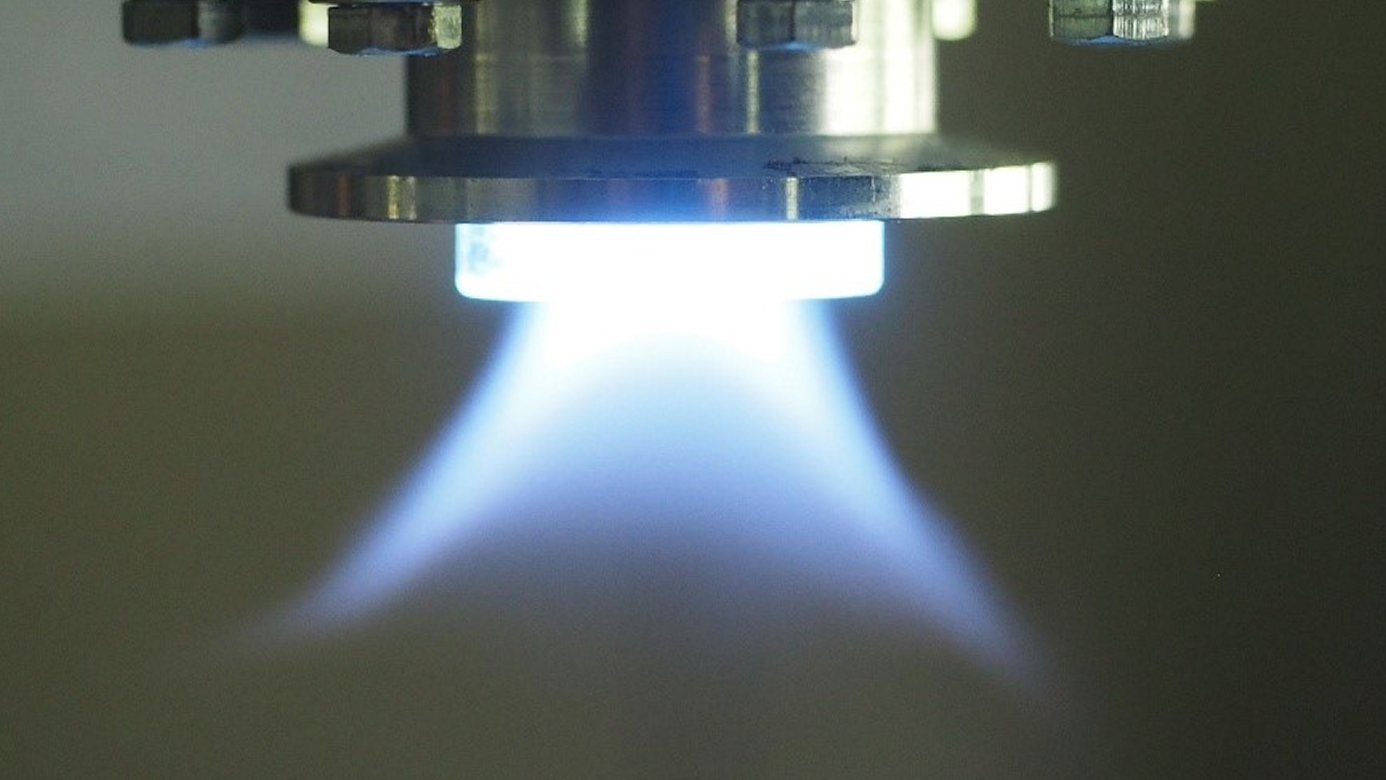

Despite its potential, raw biocrude typically contains high levels of oxygen, nitrogen, and Sulphur, elements that are undesirable for most applications. The biocrude produced within the EffiTorch project is no exception. For it to be compatible with the plasma torch systems developed in the project, the oil must have a low viscosity and a high proportion of carbon and hydrogen.

In the first round of HTL trials at Aarhus University (AU), about two metric tonnes of sewage sludge were collected from a local wastewater treatment plant in Denmark. Since the sludge had a dry matter content of only ~5%, some water was removed to increase the biomass loading and improve the process efficiency. The slurry was then processed in the pilot plant, and over roughly a six-hour period more than 10 kilograms of biocrude were produced.

As expected, this initial biocrude does not yet meet the strict requirements of the EffiTorch plasma gasification setups. It is too viscous and still contains significant levels of unwanted elements. The next step for the AU team is therefore to upgrade the biocrude through hydrotreatment—a refining process that removes impurities and improves fuel quality.

Author: Simon Fridolfsson

Keywords

HTL, Continuous hydrothermal liquefaction, Circular economy, Biocrude, Waste-to-energy, Biomass to liquid,